This consists of

- Footplate;

- Smokebox;

- Side Tanks and cab:

- Bunker.

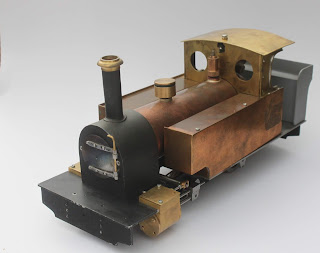

The side tanks and cab will be assembled into one unit for ease of maintenance. The footplate supports the main parts of the locomotive above the frames

Footplate

This is made up of two parts. A main platform for boiler and cab etc. and a smaller one at the front to support the front of the smokebox.

|

| Rear Footplate with Boiler Support Bracket Prior to Painting. |

Smokebox

The smokebox is fabricated from steel sheet, copper tube for the chimney with a brass cap. The door is opening, the hinge is assembled with a temporary pin.

|

| Smokebox Assembled |

Tanks and Cab

The tanks are of course dummy ones and will be used eventually to contain the gas tank and perhaps batteries. They will be attached to the footplate with bolts. The cab can be removed from the tanks by removing 4 screws and the roof is made to be removable and is held on with a screw which eventually will represent a steam chime (whistle). The window openings will have a spectacle rings added. Note the temporary screw securing the roof

|

| Cab and Side Tanks assembled |

This is made from gilding metal and brass sheet, simply because I have a supply of these materials. Gilding metal is a type of brass with a high copper content and copper migrates to the surface of the sheet, hence the copper colours of some parts which have not yet been etch cleaned. Gilding metal is a useful material for this type of work as it takes paint better than plain brass due to the copper on the surface. The tanks still need beading added to the top of the outer sheets and dummy rivets.

Bunker

This is a simple fabrication from Gilding metal assembled with silver soldered and will be secured to the rear footplate with machine screws through an angle bracket in the lower rear.

|

| Bunker Fabricated From 4 Shaped Sheets. |

Comments

Post a Comment